12. 2nd Floor, CS Nagar Denkanikotta main road, Near Hosur Railway Station, Hosur - 635109, Tamil Nadu, India .

Description

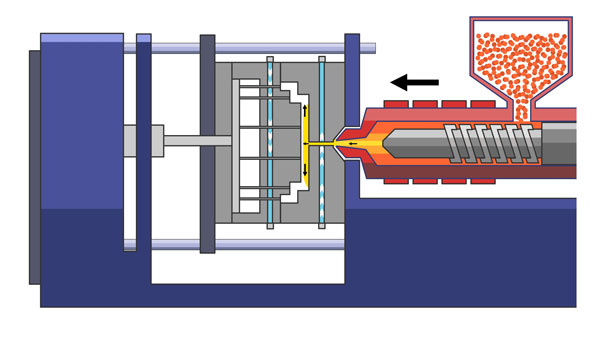

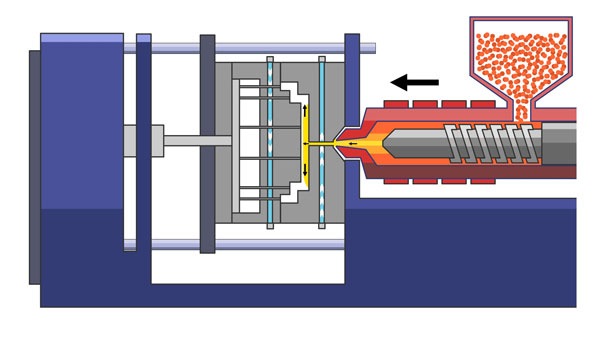

Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part. The steps in this process are described in greater detail in the next section. Injection molding is used to produce thin-walled plastic parts for a wide variety of applications, one of the most common being plastic housings. Plastic housing is a thin-walled enclosure, often requiring many ribs and bosses on the interior. These housings are used in a variety of products including household appliances, consumer electronics, power tools, and as automotive dashboards. Other common thin-walled products include different types of open containers, such as buckets. Injection molding is also used to produce several everyday items such as toothbrushes or small plastic toys. Many medical devices, including valves and syringes, are manufactured using injection molding as well

Service Info

-

Injection Moulding

-

Material

Asper customer requirement -

Machine Size

-

Similar Services

Vacuum Casting