12. 2nd Floor, CS Nagar Denkanikotta main road, Near Hosur Railway Station, Hosur - 635109, Tamil Nadu, India .

Description

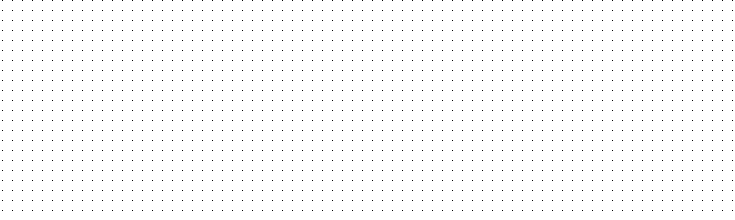

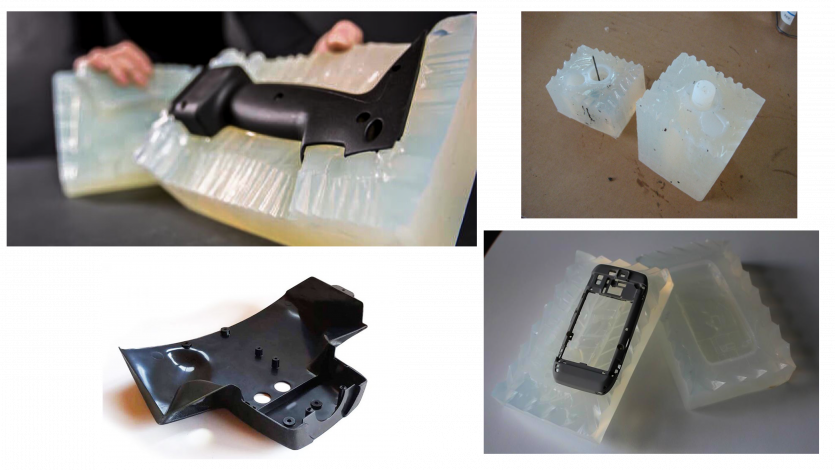

Vacuum casting(VC) is a manufacturing technology that uses a vacuum to draw liquid casting material into a mold. It differs significantly from injection molding, which pushes liquid material into a mold using a screw. The process starts with a master model, which 3D Model creates using one of its 3D Printing machining. This master model is then immersed in liquid silicone, which is cured and becomes the mold. Once it has been cut and the master model removed, the silicone mold can be put to use. This stage involves pouring casting resin into the mold, as the vacuum removes bubbles and air pockets to ensure a smooth finish. The resin part is then cured in an oven and removed from the silicone mold after cool down, which can be reused around 20 times. Each cast part is an exact copy of the original master model. It’s a perfect solution for rapid prototyping and making small batches of quality parts.

Service Info

-

Vacuum Casting

-

Material

ABS, Rubber, Nylon, PP -

Machine Size

650x650x500mm

Similar Services

Vacuum Casting